Cleaning and cleansing wipes have become a staple not only in homes, but also in many commercial spaces due to how versatile and convenient they are as a cleaning solution. So how exactly are these wipes made?

Here are some key focal points when creating the perfect wipe:

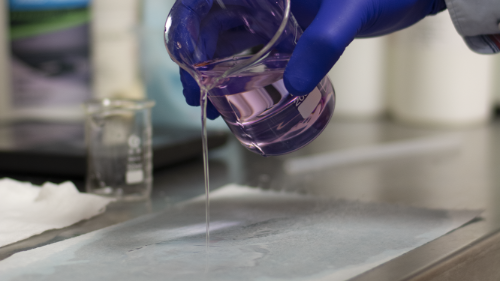

Formulation – what cleaning solution will be used?

As cleaning wipes are so versatile and can be used in all areas of the home or workplace, we create a large variety of wipes suitable for all of our customers needs. Countless hours are spent in our in-house laboratory, where our R&D and technical team formulate, test, improve and repeat until we have the best wipe for your needs.

We produce everything from our Vinco® Tuffscrub Strong Industrial Cleaning & Degreasing Wipes, perfect for those in the construction or joinery industries, to our Vinco® ZeroWipe Bio and Plant Cleaning & Sanitising Wipes, a perfect solution for eco-conscious businesses. This means that we have a wide range of formulations that can be applied to our wipes to ensure that we have the perfect cleaning solution for you and your business.

What are the wipes made of?

Wipes are typically made from nonwoven fabrics. Nonwoven fabrics are chosen for their durability, absorbency, and softness. These fabrics are typically made from a blend of fibres such as polyester, rayon, and polypropylene, however our Vinco-ZeroWipe range are completely plastic-free.

The fibres are bonded together using various methods like heat, chemicals, or mechanical action, creating a fabric that is strong yet soft enough for effective cleaning without scratching surfaces.

Packaging our wipes

Once the roll of wipes has been cut to size and perforated for ease of separation, the rolls of wipes are placed into their containers, either our large tubs containing 500-2000 wipes or our smaller tubs containing 50-200 wipes, ready to be saturated. Each container will then move further down the line, where they will be labelled to reflect which cleaning solution has been applied.

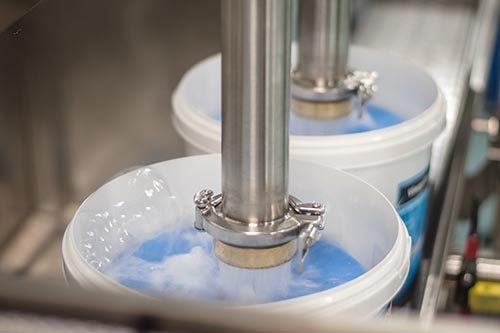

Saturating the wipes

Once placed in their containers, the rolls of wipes move further down the manufacturing line, ready to be saturated. This is done mechanically, with the perfect amount of cleaning solution being dispensed into each container of wipes to ensure that every wipe is equally coated to ensure optimum performance every time.

Lidding and labelling

Once each tub has been saturated, they are then sealed and lidded. A product information label is applied and a batch number and expiry date is printed on the tub or packet.

Quality Control

They have now neared the end of the production process. Every tub or packet then passes through a metal detector to ensure there are no foreign objects within the wipe or packaging and to ensure we meet the highest accreditation standards such as ISO and BRC. The wipes are then packed and shipped out to our happy customers!

Conclusion

With over 30 years of being at the forefront of the cleaning and hygiene industry, we have become a market leader in the manufacturing of wet wipes. Providing many industries including Facilities, Education, Food Processing, Food Service and Healthcare.

Each product featured in our range has passed through rigorous testing before making its way from our design team to our production line. Each product is then assembled by selecting the perfect wipe for each job, packaging and saturating these with the best possible formula, before labelling each container and sending them to quality control.

HC Innovations pride ourselves not only on our extensive range of quality products, but our ability to create the perfect solution for each of our customers. f a client requires their own formula developed or whether it’s an adjustment to an existing solution, this is where it can become a reality and innovation really comes alive.

Perhaps you require a product for a particular purpose or a formula to accomplish a particular task?

Perhaps it’s a certain texture of substrate fabric or a scent in a wiping product? Our R&D personnel and chemists can work with you to create the product you require.

Contact us for more information on how we can help you find your perfect wipe.